LensAFM — Extend the resolution of your optical microscope

Overview

LensAFM — Extend the resolution of your optical microscope

Mountable on virtually any optical microscope or 3D optical profilometer

Extend your resolution capabilities by a factor of up to 100

Combine optical and AFM techniques

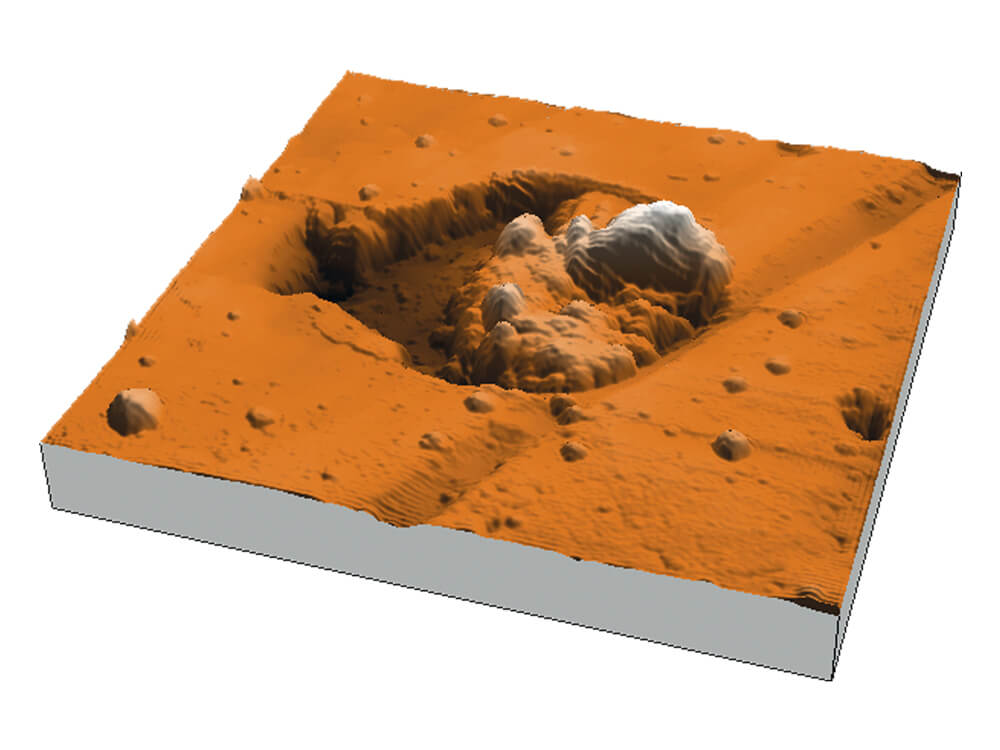

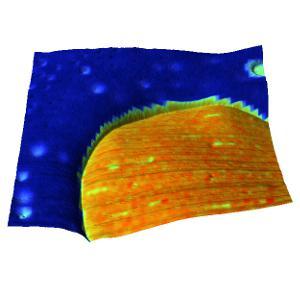

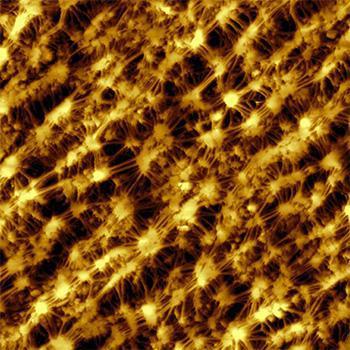

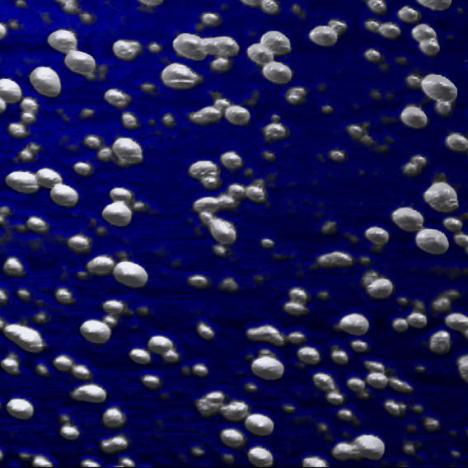

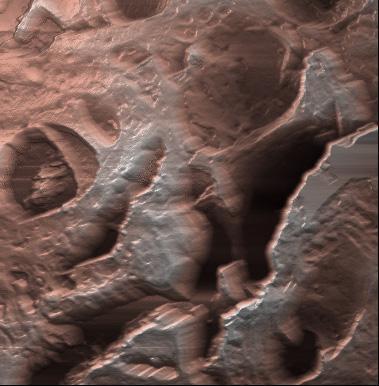

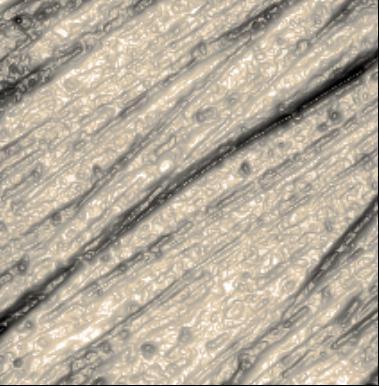

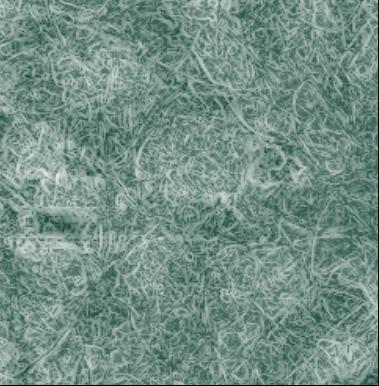

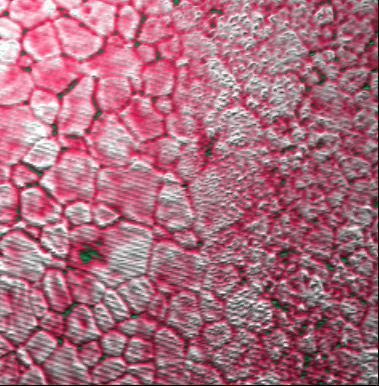

The Nanosurf LensAFM is an atomic force microscope that continues where optical microscopes and profilometers reach their resolution limits. It is mounted like a normal objective lens, thus extending the resolution and measuring capabilities of these instruments. The LensAFM not only provides 3D surface topography information, but can be used to analyze various physical properties of a measurement sample as well.

"The unique combination of compact design, optical access, and intuitive operation of the LensAFM made it the perfect platform for our instrument development. We believe that much of the success of our project has been achieved through the excellent communication that we have enjoyed between ourselves, Nanosurf, their UK distributor Windsor Scientific, and AFM probe manufacturer Nanosensors. We now look forward to future developments with the LensAFM to optically probe magnetic materials deep into the nanoscale."

Senior Experimental Officer (SEO)

Exeter Time Resolved Magnetism Facility

University of Exeter, UK

More on Dr. Keatley's work

Download the LensAFM Brochure

Perform AFM measurements with the instruments you are used to

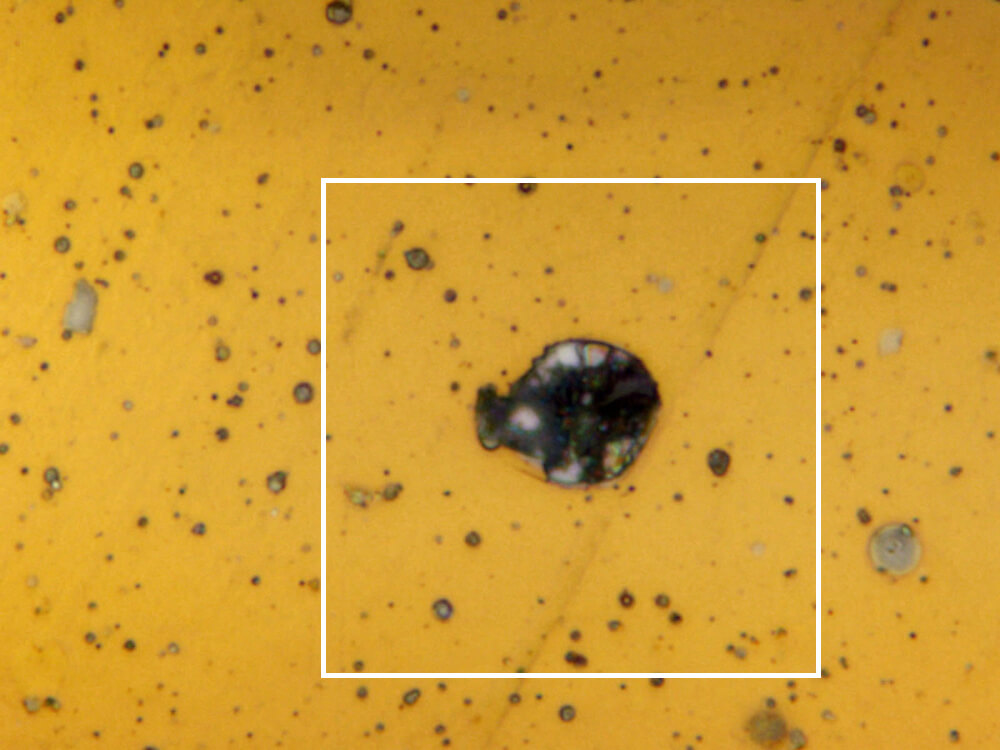

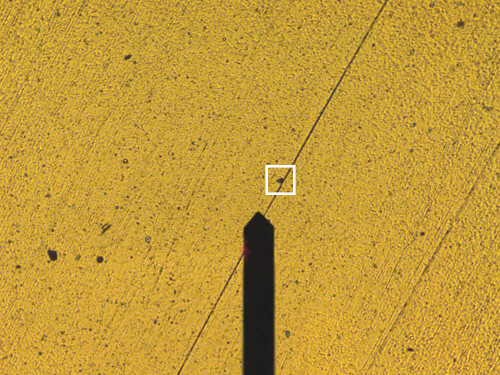

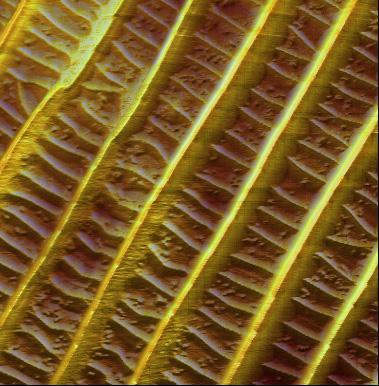

In an ever increasing number of situations, researchers want to combine optical and atomic force microscopy techniques. The ease of use, screening capability and (lack of) sample preparation requirements of optical microscopes is almost unparalleled. However, sometimes a 100x objective is not enough and you would like to have a closer look at some small features that go beyond the resolution of the instrument. In a regular laboratory setting you would require two dedicated instruments and it would be necessary to transfer the sample from one device to the other. With the LensAFM this is not the case. With its exceptionally small design and clever mounting mechanism all you need to do is rotate the turret on your optical microscope or profilometer and run the scan.

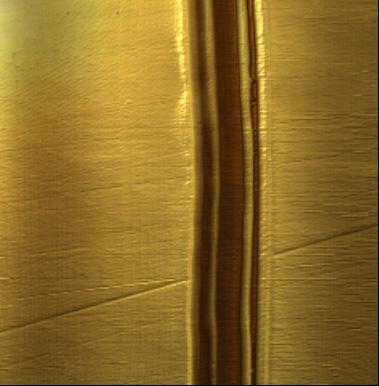

The LensAFM integrates perfectly into your workflow: upon mounting it on your optical microscope's turret — like a regular objective lens — you screen the sample with normal objectives to find areas of interest. Subsequently, the area of interest is readily found again using the integrated 8x optical lens, and you can then perform your AFM measurement to get higher resolution 3D information: work in the way you are used to, but with a huge boost in resolution and capabilities.

The LensAFM has a quick release mechanism to easily mount and unmount the LensAFM to and from the turret. The kinematic mounting guarantees that you will replace it with better than 10 µm accuracy. Alignment grooves on the chip mount additionally ensure that the tip of the next cantilever is within 4 µm of the same position allowing to find the same feature again, even after a cantilever exchange. And thanks to these alignment grooves, you don't even have to perform a laser alignment on the cantilever, saving additional time.

The LensAFM brings all these measurement capabilities to your optical microscope, without rethinking of your whole workflow. Watch the video to see for yourself how easy it is to boost your capabilities.

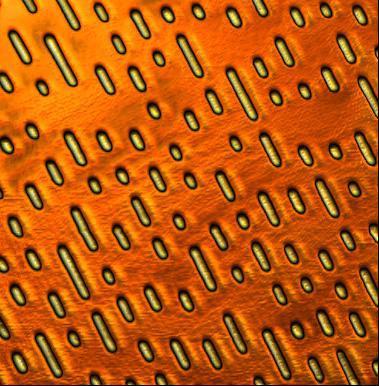

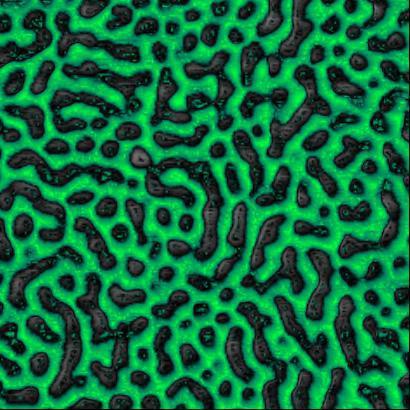

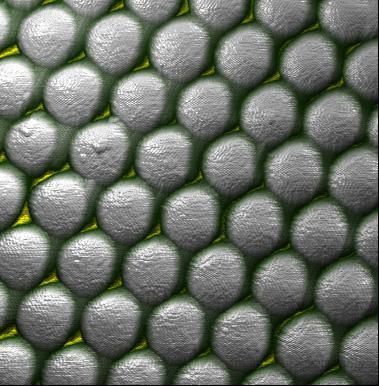

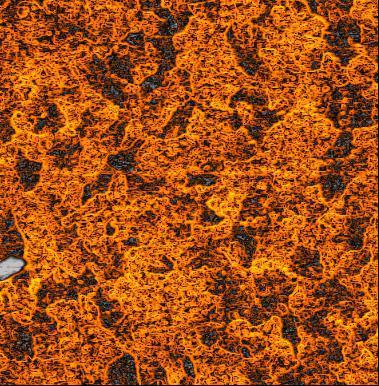

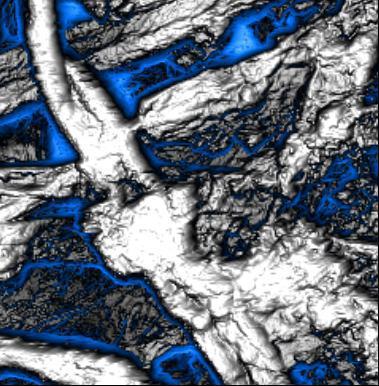

Boost the capabilities of your optical microscope

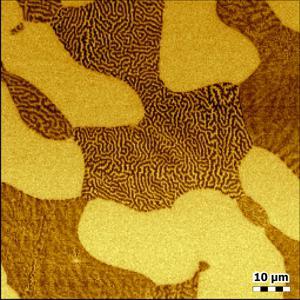

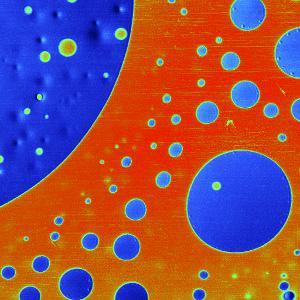

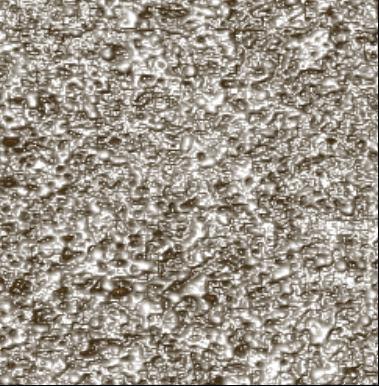

Since the resolution of optical microscopy is limited by the wavelength of light, there is a barrier in the resolution you can achieve with your optical system. In an ever increasing number of applications, this calls for the combination of optical and atomic force microscopy. In addition, AFM overcomes problems characterizing transparent samples or samples otherwise difficult to assess optically. But not only the topography of a sample is of interest: AFM also allows knowledge of other material properties to be acquired, e.g. surface roughness, hardness variations, magnetism, or electrical conductance/resistance.

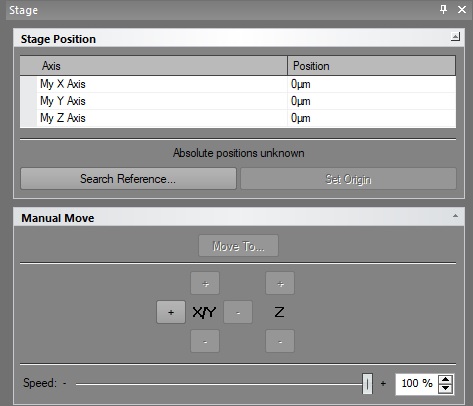

LensAFM imaging modes

This overview shows which modes the instrument is capable of. Some modes may require additional components or software options. For details, please contact us.

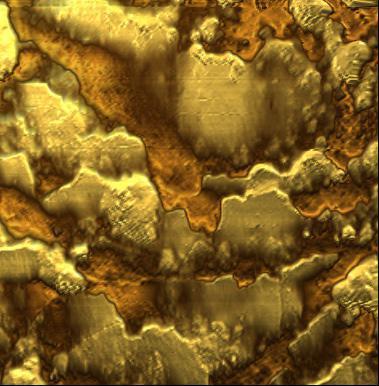

Standard imaging modes

Static Force Mode

Dynamic Force Mode (Tapping Mode)

Phase Imaging Mode

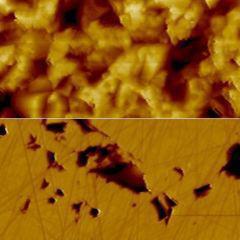

Magnetic properties

Magnetic Force Microscopy

Electrical properties

Conductive AFM (C-AFM)

Electrostatic Force Microscopy (EFM)

Scanning Spreading Resistance Microscopy (SSRM)

Mechanical properties

Force Modulation

Force Spectroscopy

Force Mapping

Other measurement modes

Lithography and Nanomanipulation

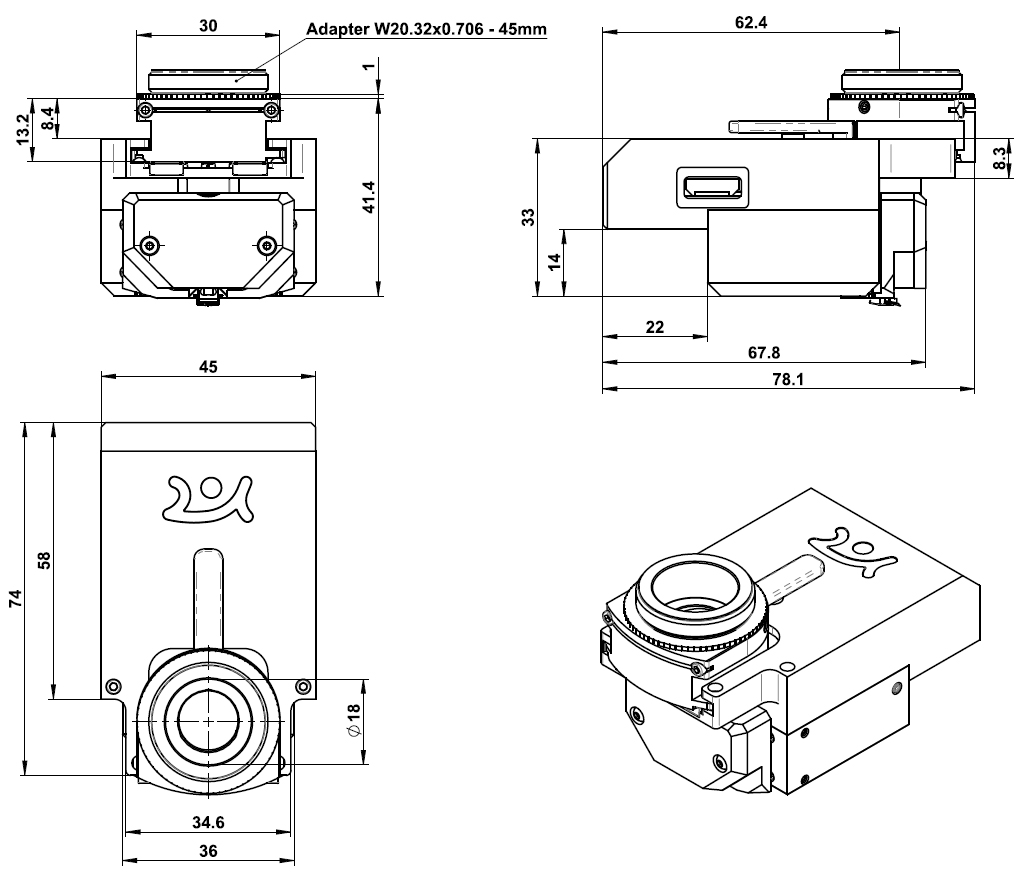

Scan head dimensions