Overview

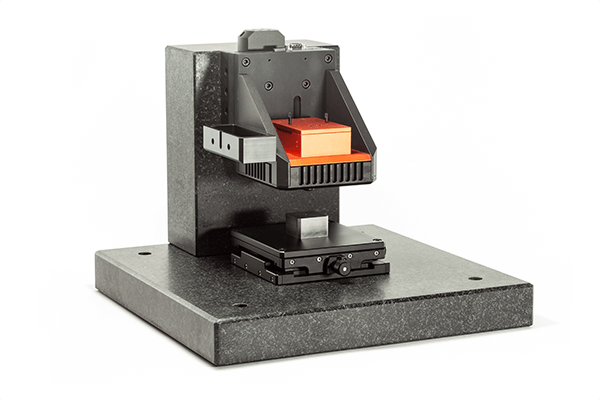

Flex-Mount — The essential AFM for custom integration

Flex-Mount is a unique AFM that can be configured to acquire high-resolution information on large, non-planar and demanding samples. The Flex-Mount solution combines the superior resolution and performance of the Nanosurf FlexAFM scan head with the integrability of the Nanosurf NaniteAFM. The result is an AFM that can easily be attached to one of Nanosurf’s large, custom-built motorized translation stages and is thus able to characterize the surface of samples with weights and dimensions virtually no other AFM system can handle.

Proven performance and reliability

Automated measurements for additional ease of use

Customizable stages to handle large samples of any shape and size

Download the Flex-Mount brochure

Practical details that really matter in daily use

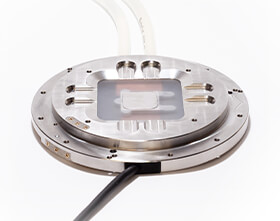

Cantilever holders with magnetic attachment to the scan head make the task of replacing cantilevers an easy one.

The same cantilevers holders also include alignment structures for use with cantilevers containing alignment grooves. This provides micrometer repositioning accuracy, circumventing laser alignment and allowing you to find the same sample features after cantilever exchange.

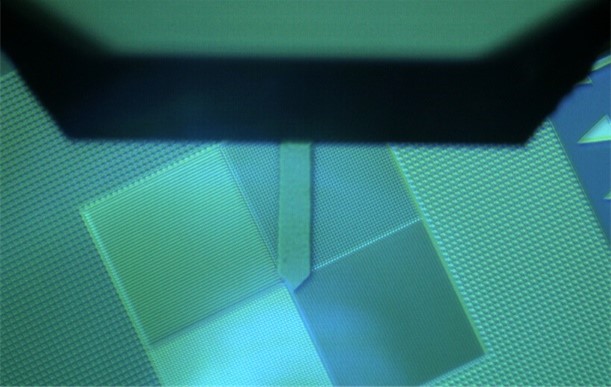

The Flex-Mount also includes an integrated top view and side view camera, which are of great help during sample approach and positioining, allowing you to precisely align the tip with the feature of interest on the sample.

Top view

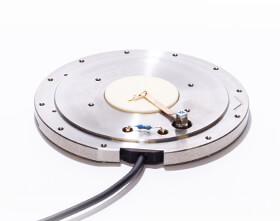

Side view

Precision and performance

The Flex-Mount uses a linear electromagnetic scanner for XY movement. This scanner delivers an average linearity deviation of less than 0.1% over the full scan range, top-ranking on the AFM market. The Z-axis is piezo-driven, with a position sensor that enables closed-loop operation. A sensitive cantilever detection system can measure well into the MHz frequency range. The scan head is connected to the full-featured, 24-bit C3000i controller with digital feedback and 2 dual-channel lock-in amplifiers.

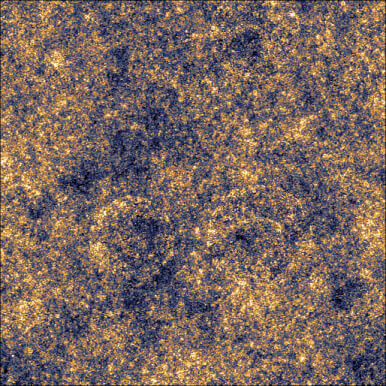

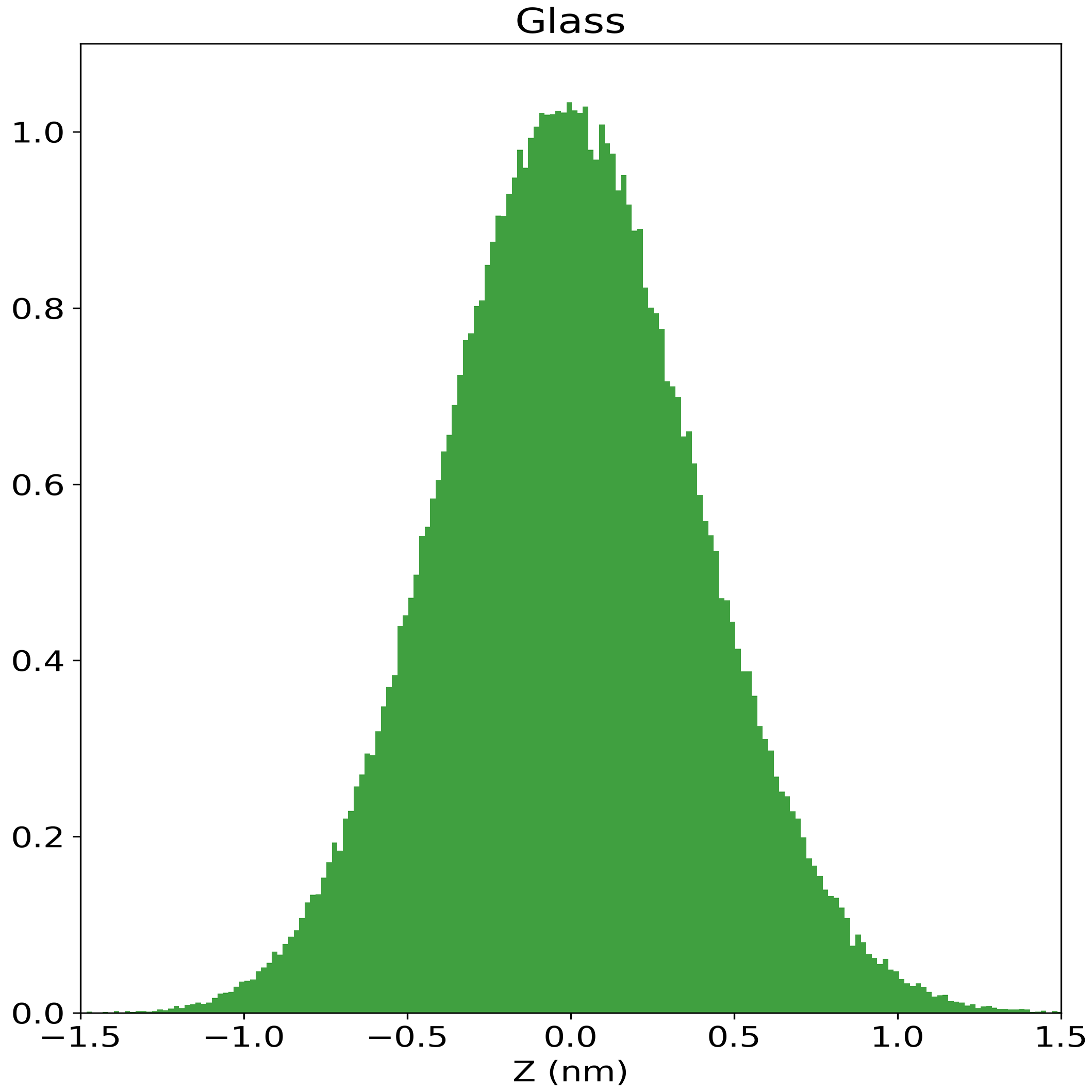

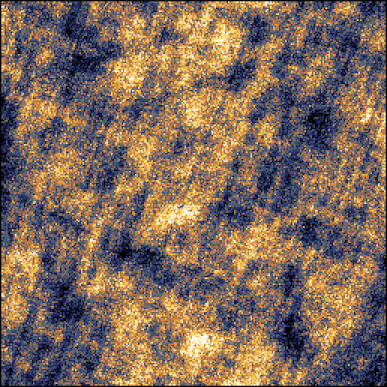

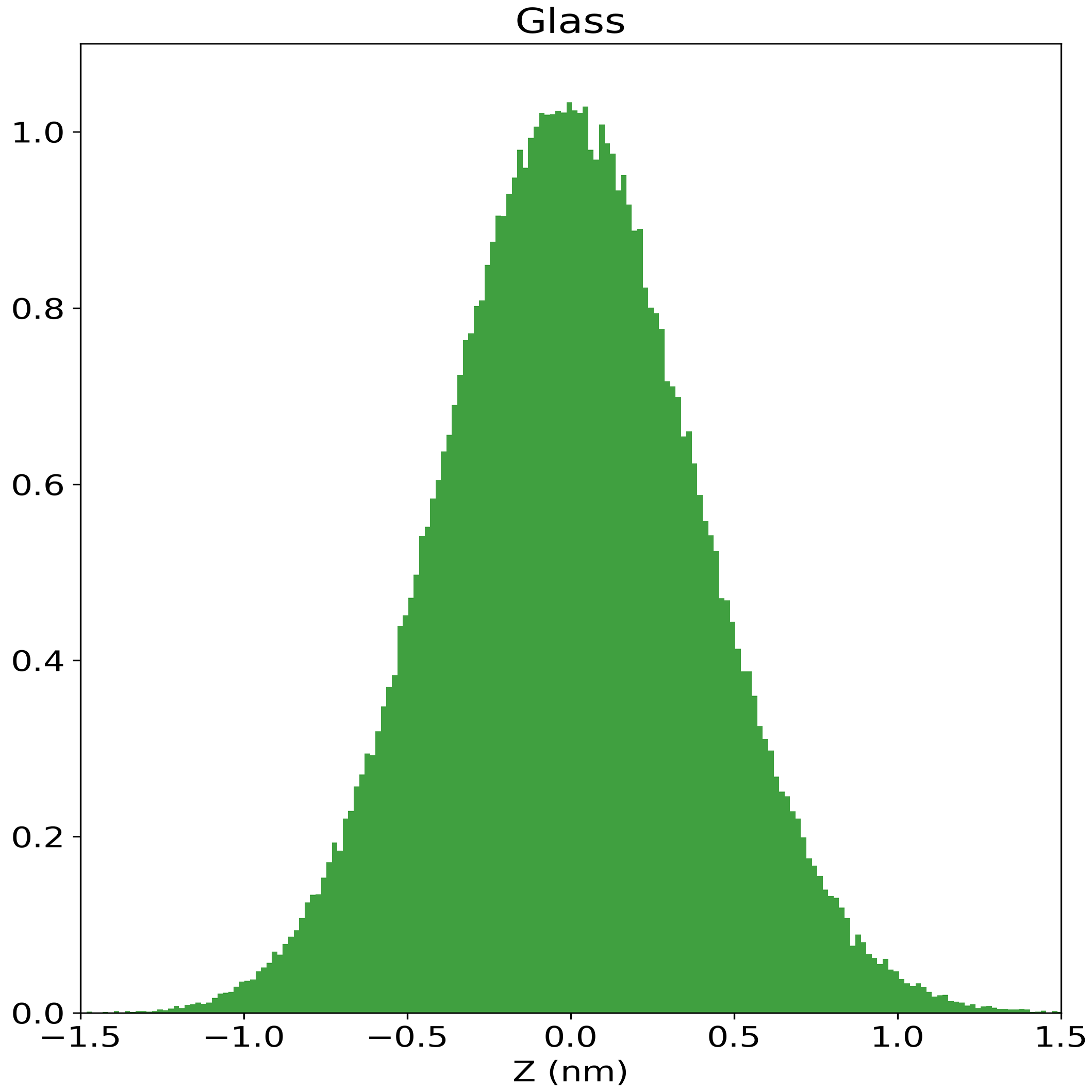

Glass roughness

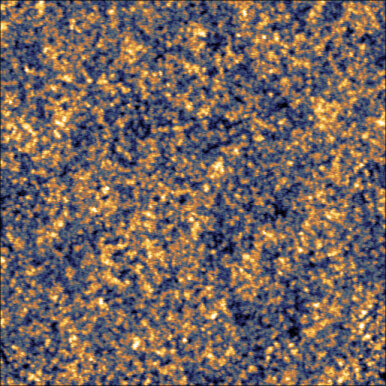

AFM topography of glass; overview

(scan size: 5 µm × 5 µm)

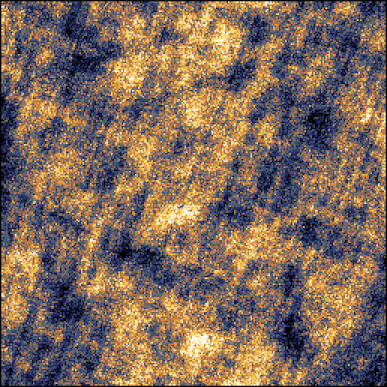

AFM topography of glass; details

(scan size: 1 µm × 1 µm)

Histogram of the topography data.

Sa = 313.10 pm, Sq = 393.66 pm, Sy = 4420 pm, Sp = 1981.7 pm, Sv = -2468.6 pm, Sm = -9.313 fm

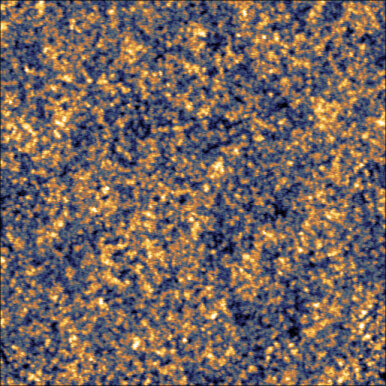

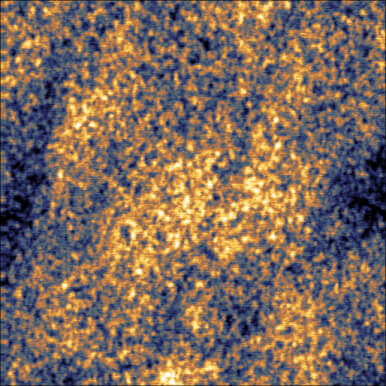

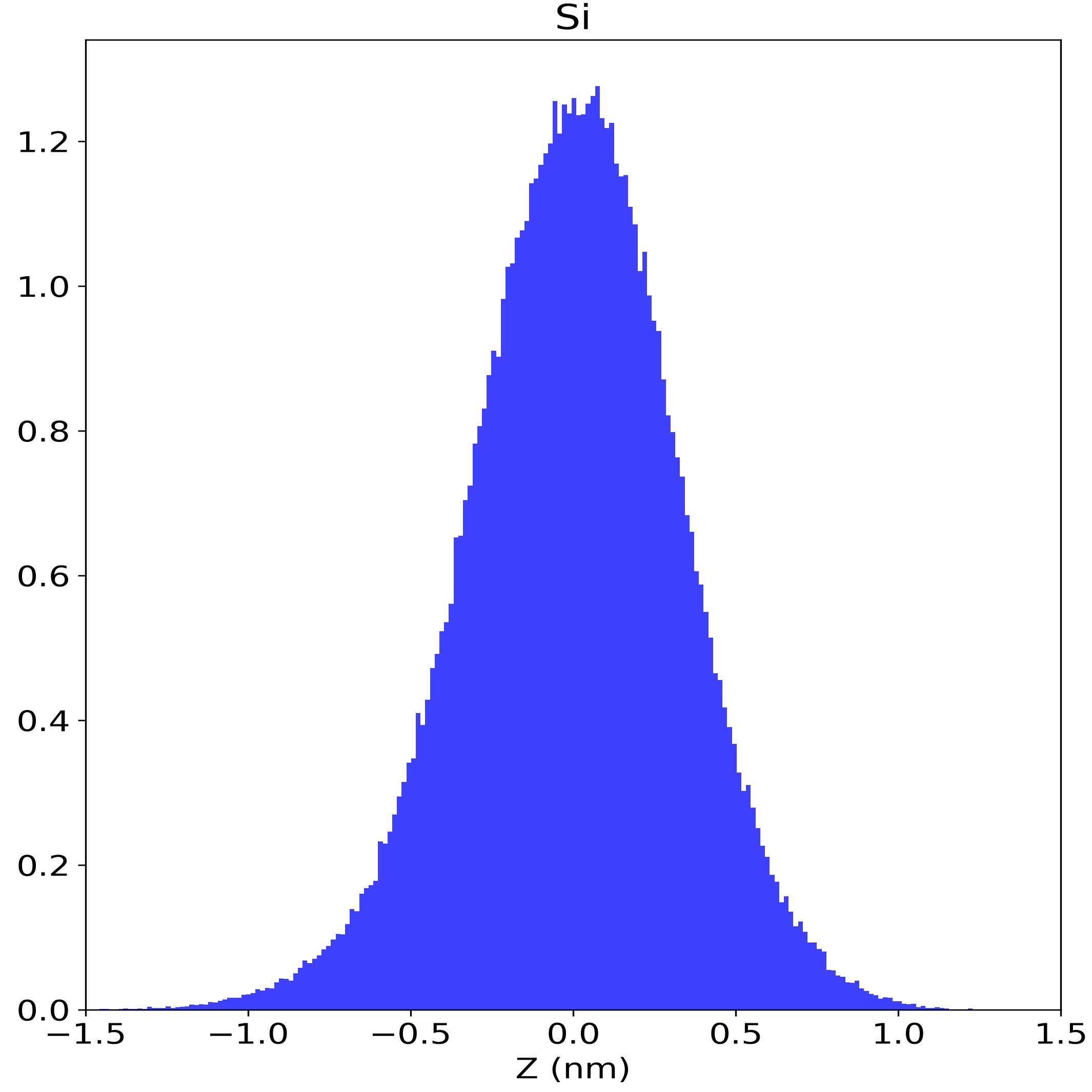

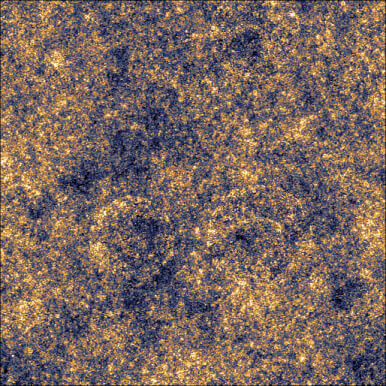

Silicon wafer roughness

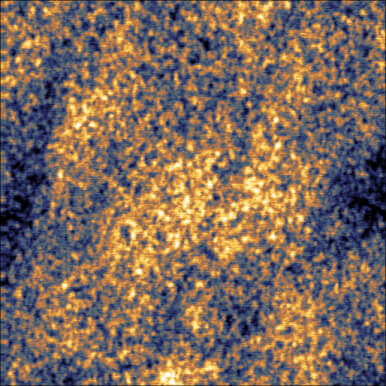

AFM topography of a silicon wafer; overview

(scan size: 5 µm × 5 µm)

AFM topography of a silicon wafer; details

(scan size: 1 µm × 1 µm)

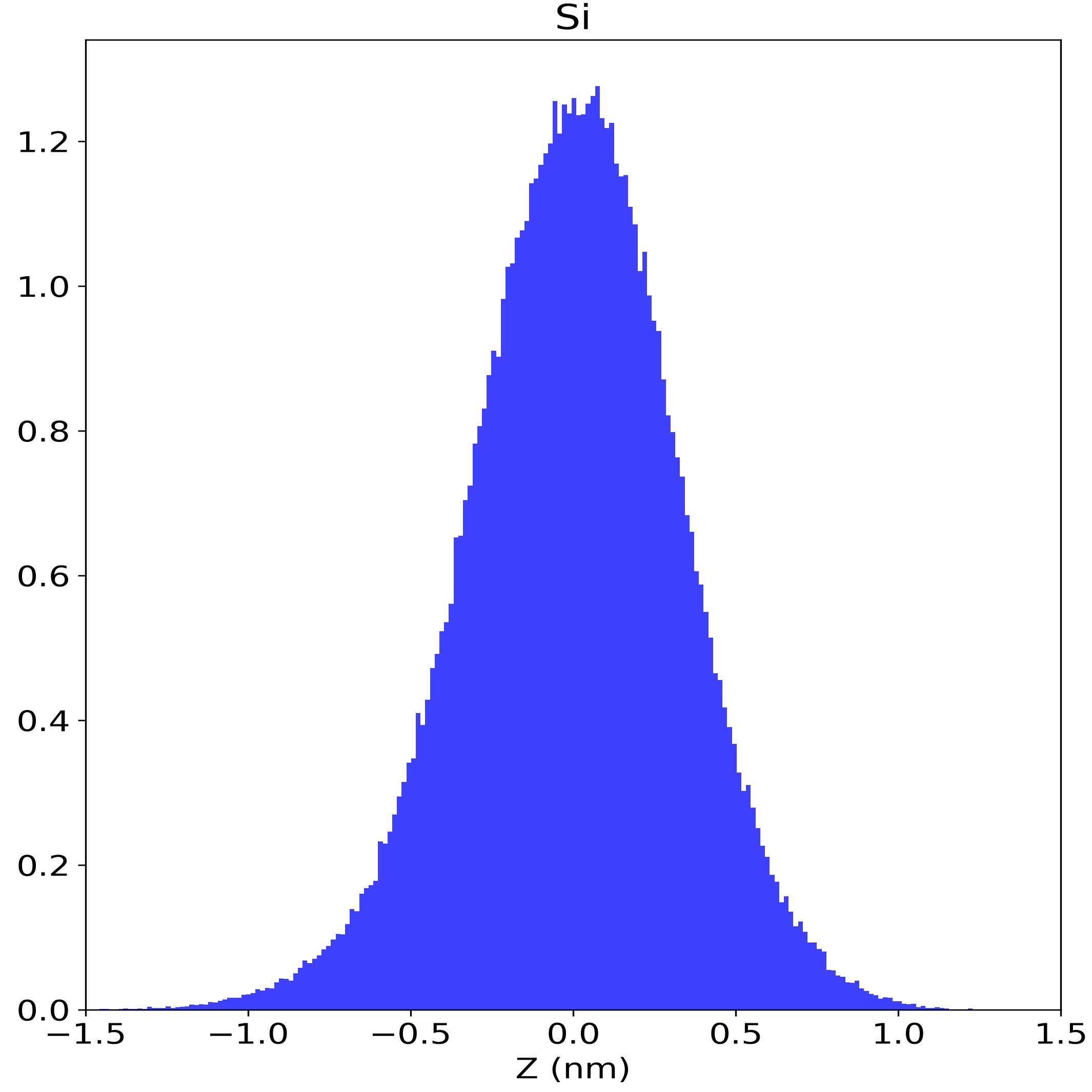

Histogram of the topography data.

Sa = 318.46 pm, Sq = 397.54 pm, Sy = 3335 pm, Sp = 1685.2 pm, Sv = -1670.4 pm, Sm = -19.499 fm

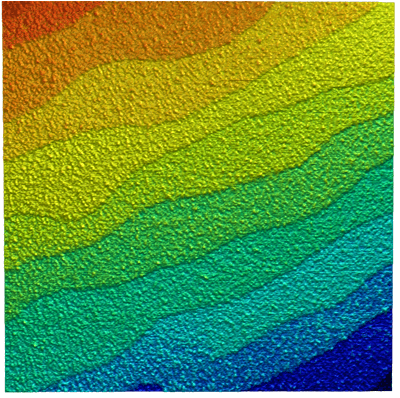

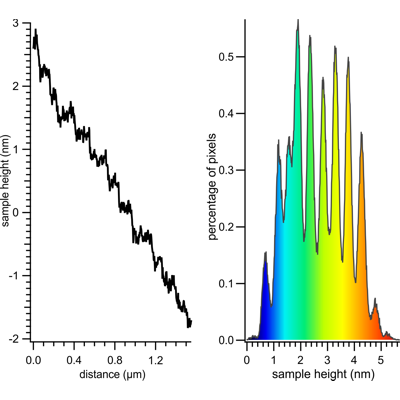

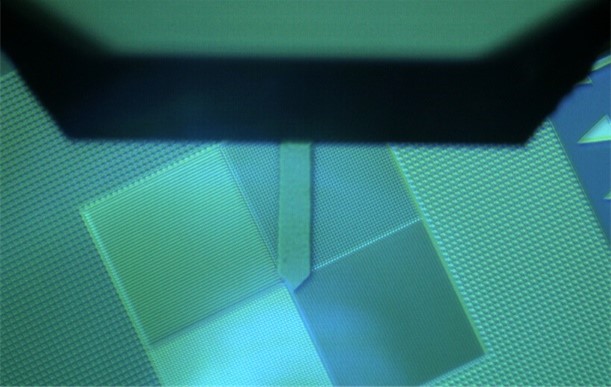

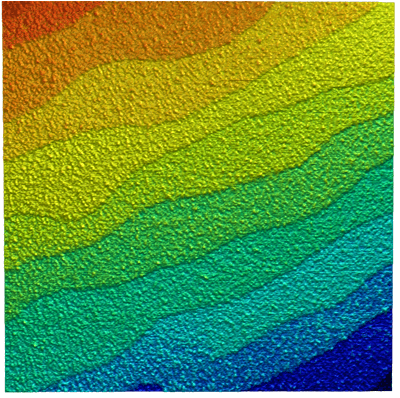

Steps of Strontium Titanate

Topography showing steps of strontium titanate

(scan size: 1.1 µm × 1.1 µm)

Section profile and height distribution

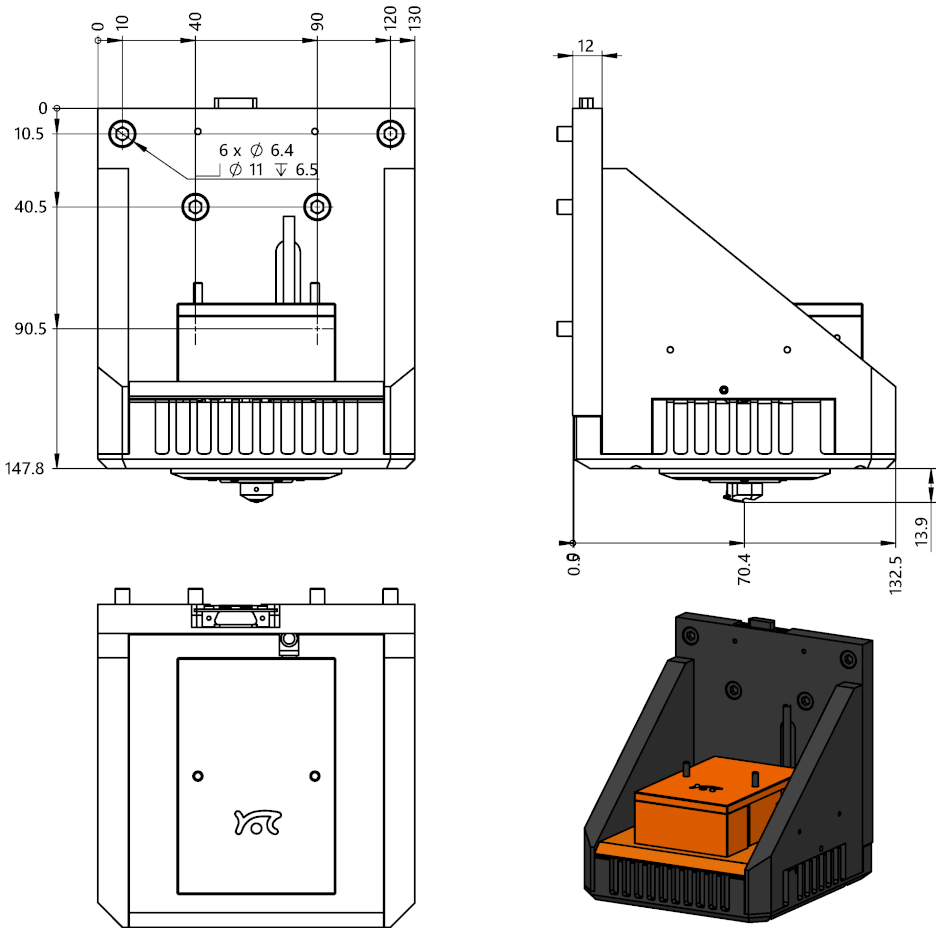

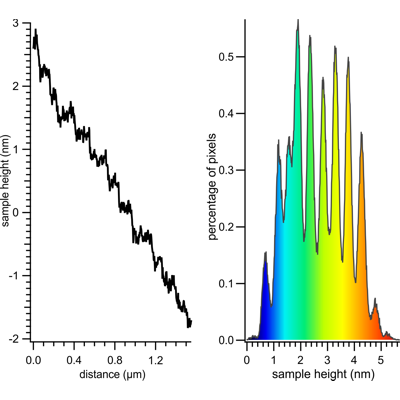

Scan head dimensions

All dimensions in mm.

AFM Modes

Flex-Mount imaging modes

This overview shows which modes the instrument is capable of. Some modes may require additional components or software options. For details, please view the brochure or contact us directly.

Standard imaging modes

Static Force Mode

Lateral Force Mode

Dynamic Force Mode (Tapping Mode)

Phase Imaging Mode

Thermal imaging modes

Scanning Thermal Microscopy (SThM)

Magnetic properties

Magnetic Force Microscopy

Electrical properties

Conductive AFM (C-AFM)

Piezoelectric Force Microscopy (PFM)

Electrostatic Force Microscopy (EFM)

Kelvin Probe Force Microscopy (KPFM)

Scanning Spreading Resistance Microscopy (SSRM)

Mechanical properties

Force Spectroscopy

Stiffness and Modulus

Adhesion

Unfolding and Stretching

Force Mapping

Other measurement modes

Lithography and Nanomanipulation

Electrochemical AFM (EC-AFM)

Integration examples

Integration examples

Total freedom with Nanosurf custom sample stages

Measure irregular samples just as easily as regularly shaped, planar and non-planar samples. Let us build the ideal automated solution for you, or integrate the Flex-Mount with your existing measurement stages. The Nanosurf portfolio has many options for both software and hardware integration.

We're happy to be of assistance!

This video shows the complex coordinated stage tilting, rotating and translation movements possible to allow AFM measurements on any plane or edge of a difficult sample/shape.

This video shows the tilting, rotating and translation movements required to measure any area on a regularly formed concave sample.

Motorized XYZΦ translation stage for extra large samples

| Description |

Specification |

| Max. Traverse path X/Y/Z/Φ: |

230/485/20 mm / 360°

|

| Step size X/Y/Z/Φ: |

0.5/0.5/0.5 µm / 0.001° |

| Step size X/Y/Z/Φ: |

0.5/0.5/0.5 µm / 0.001° |

| Repositioning accuracy: |

± 1/1/1 µm / 0.001° |

| Absolute accuracy: |

± 15 µm |

| Max. velocity: |

30/30/3 mm/s / 7°/s |

| Sample platform size: |

⌀500 mm |

| Sample size: |

⌀500 mm × 80 mm |

| Sample weight: |

max. 20 kg |

| Stage size: |

1350 mm × 950 mm × 1360 mm |

| Stage weight: |

1300 kg |

| Stage technology: |

Linear motors, spindle-stepper motor, harmonic drive, air bearings

|

| Noise level: |

< 40 pm |

Motorized XYZ translation stage

| Description |

Specification |

| Max. Traverse path X/Y: |

235 mm

|

| Motorized Z-travel: |

50 mm |

| Sample platform size: |

240 mm × 240 mm |

| Resolution X/Y: |

0.1 µm |

| Repositioning accuracy X/Y: |

1 µm |

| Max. sample size: |

240 mm × 240 mm × 45 mm |

| Stage size: |

490 mm × 530 mm × 350 mm |

| Stage weight: |

Approx. 60 kg |

| Noise level: |

< 35 pm |

Manual translation stage

| Description |

Specification |

| Sample platform size X/Y: |

400 mm × 300 mm |

| Tip – rear wall distance: |

113 mm |

| Max. sample size: |

400 mm × 300 mm × 105 mm |

| Stage size: |

400 × 400 × 400 mm |

| Stage weight: |

Approx. 55 kg |

Options & Accessories

Flex-Mount options and accessories

Standard sample holder

Samples up to 100 mm in diameter, central magnet to hold small samples on pucks, clips to hold larger samples.

Petri dish holder

Holds petri dishes of 35 or 50 mm diameter and height up to 10 mm.

Heater sample holder

Heats samples up to 250 °C. Needs TEC controller CH1.

Cooling & heating sample holder

Temperature range of -35 °C to 180 °C. Needs TEC controller CH1, pump and temperature reference unit.

TEC contoller CH1

Temperature monitoring and control, temperature stability < 0.05 °C.

Pump and temperature control unit

Used with cooling & heating sample holder. Includes a pump and temperature control unit for the circulating coolant.

C-AFM sample holder

Sample holder for advanced conductive AFM option. Current range of ± 25 nA with a sensitivity of 108 V/A. Current noise 3 pA at 4 kHz bandwidth.

150 µm z-stage

Z-range extension of up to 150 µm for long range force spectroscopy experiments. For petri dishes of 35 mm diameter and 50 mm diameter.

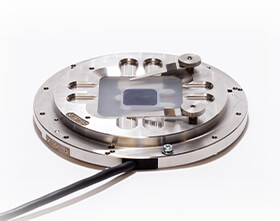

Variable magnetic field sample holder

Variable in-plane magnetic field, integrated Hall sensor, Max. field – 720 mT (2 mm gap), Filed resolution – 0.1 mT, Sample size - up to 10 x 10 mm2.

Digital inverted microscope option

The DIMO can be integrated with Isostage 300, SMA optical port for illumination, Motorized centering and focus, Nikon objective, Fluorescence option with a fiber coupled light source.

EC cell

For electrochemical experiments, PEEK or PVDF EC cell in a stainless-steel frame. Built-in electrode and tubing feedthroughs.

Environmental control chamber

For sample measurements under controlled environments. Expanding sealing membrane. Gas inlet and outlet.

Samples & mode kits

Mode Kits

- FlexAFM standard conductive AFM mode option

- Dynamic force mode kit

- EFM mode kit

- Force modulation mode kit

- Lateral force mode kit

- Phase imaging mode kit

- Standard liquid mode kit

- Standard lithography kit

- Standard MFM mode kit

- Standard spectroscopy mode kit

- Static force mode kit

Cantilever holders

- Cantilever holder liquid/air flat

- Cantilever holder liquid/air flat conductive

- Cantilever holder liquid/air flat grooveless 0.3 mm

- Cantilever holder liquid/air flat grooveless 0.6 mm