本文所描述的压电力显微法或压电响应力显微法(PFM)是扫描探针显微家族中用于研究纳米级材料压电现象的电学模式。PFM在测量纳米级形貌的同时,还测量材料对电压施加的机械响应。

压电性就是在某些固体材料中积累的电荷,并对机械应力作出反应。许多材料是压电材料,某些晶体,陶瓷和生物材料,例如牙齿,骨骼,DNA和各种蛋白质。对于生物样品,其固有的压电性可能与其力学生物学有关。压电效应是由外加机械力产生的内部电荷引起的。逆压电效应是由外加电场产生的内部机械应变引起的。由于原子力显微镜基本上是基于针尖和样品之间的实际机械接触,因此它特别适合在纳米尺度上研究材料的这一现象。

铁电材料是压电材料的子集,通常也用PFM来研究。铁电体表现出自发极化,通过施加电场可以在方向上反转。在具有铁电畴的材料中,反转外部电场会反转铁电畴的主要方向。切换到新的方向滞后于场的变化。这种效应称为磁滞现象。铁电特性在传感器、驱动器、探测器和存储器等电子设备的许多重要应用中都起到很大的作用。 PFM是一种可在微米和纳米长度范围内”看见“铁电畴的独特的工具。

PFM基于逆压电效应,即电压施加到样品上导致样品扩展。然后用PFM测量样品的机械延伸。在PFM中测得的样品延伸或位移很小,只有几纳米。

PFM还经常用于研究铁电畴。所施加的偏置电压可以切换铁电畴的区域,从而以纳米级分辨率探索铁电畴的结构和形成。通过这种方法,形貌和相应的铁电畴得以以纳米或微米分辨率成像。

PFM 在调幅模式下运行,这是一种动态力模式,其中导电AFM探头以其共振频率被驱动(此模式也称为轻敲模式)。需要一个导电探头作为对样品施加偏置电压的一种方法。常见的导电涂层是铂,金,钨和导电金刚石。这些悬臂不昂贵且可商购。

在AFM尖端和样品表面之间施加交流电压,以在样品中产生逆压电场。由于施加的电压,样品将收缩或膨胀,从而导致PFM悬臂发生偏转。悬臂偏转通过标准光电二极管检测器进行监控,并通过锁相放大器进行解调。振荡悬臂的PFM振幅和相位均受到监控。 PFM振幅信号提供有关信号强度以及材料的压电张量的信息。 PFM相位信号提供有关极化方向的信息。

PFM是一种无损AFM测试手段。 它只需极少的样品准备就可以对材料的压电响应进行高分辨率测量。 然而,图像采集通常非常缓慢,需要几十分钟。 另外,针尖磨损会显著改变针尖与样品的相互作用,从而影响PFM对比度。 不幸的是,很难直接监控针尖磨损,磨损后在图像中会产生伪影。

压电力显微示例

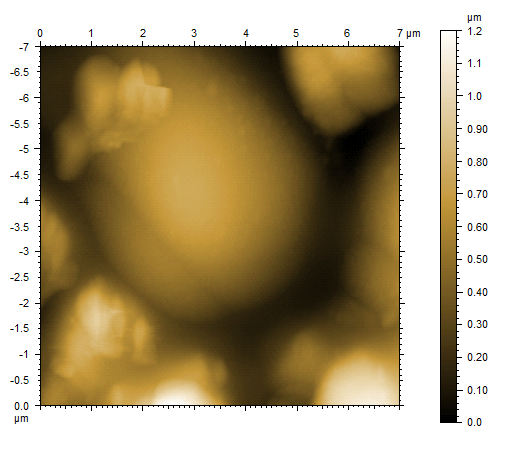

压电材料通常用于扬声器,压力传感器和接触式麦克风的换能器盘中。 这种盘上的压电层由厚膜涂覆工艺产生的,具有多晶结构。 下图是100µm厚的普通压电材料锆钛酸铅(PZT)的7µm x 7µm PFM图像。 左侧的地形图显示了多晶材料的形态。 PFM相位信号显示在右侧,揭示了此样本中的铁电畴。

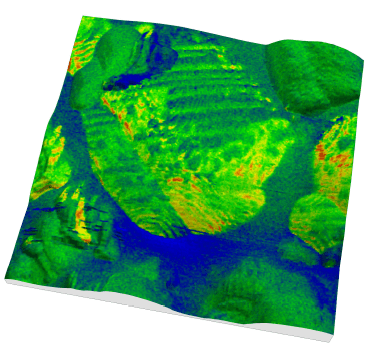

压电力显微的另一个示例如下所示。 压电传感器和移动电话使用一种常见的光学透明材料,称为铌酸锂(LiNbO3)。 在这幅10µm x 10µm的图像中,PFM相位信号叠加到现在由于PFM相位信号而着色的地形上。 在此图像中,在成像时将7.5V 交流电压施加到悬臂样品接触点。 作为响应,样品周期性地相对于激发频率同相或反相膨胀或收缩。 通过PFM图像的对比度可以轻松观察到这些压电畴。

PFM 存在于 CoreAFM 和 FlexAFM 产品线中.