As a long-time Nanosurf customer, I highly value Nanosurf’s exceptionally fast and competent expert-level support. They were of great help in ironing out technical issues with our initial glovebox implementation and responded quickly and positively to all of my requests.

As a long-time Nanosurf customer, I highly value Nanosurf’s exceptionally fast and competent expert-level support. They were of great help in ironing out technical issues with our initial glovebox implementation and responded quickly and positively to all of my requests.

One of the challenges in AFM measurements and especially Kelvin probe force microscopy is the effect of surface contamination. Water films can strongly diminish the feedback behavior of dynamic AFM, inducing tip changes and mode hopping. The surface potential of relatively inert surfaces like graphene is also strongly influenced by the various contaminants present under ambient conditions. The effort to move the experiments to high-resolution AFM systems running in ultra-high vacuum is, however, often too high or even impossible in case of sensitive surfaces.

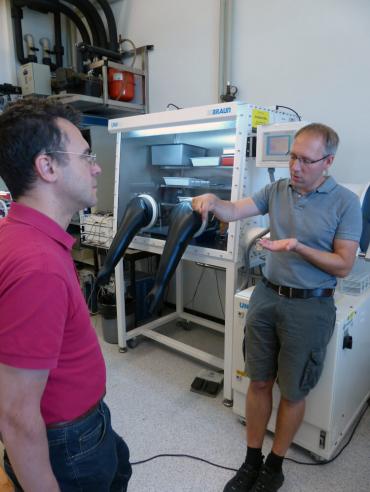

Therefore, we installed a Nanosurf Flex-Axiom system and an active vibration isolation solution in a N2 glovebox with an O2 and H2O concentration of less than 0.1 ppm. The Flex-Axiom is ideally suited for glovebox operation because of its performance and small footprint, even allowing us to move the AFM in and out of the glovebox through the antechamber without having to disassemble the entire glovebox or disrupt the environmental control of the N2 atmosphere, as would be the case for many other AFM systems.

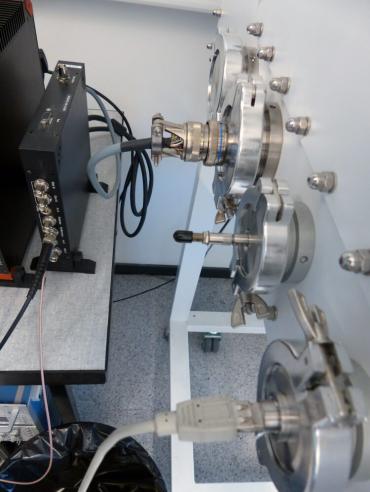

Custom-built, air-tight cable connectors were installed in the side panel of the glovebox, which allows the C3000 controller of the Flex-Axiom system to reside outside of the glovebox, freeing up valuable workspace for experiments and further equipment on the inside. Included in our glovebox setup, for example, is an annealing stage, allowing us to anneal samples inside the controlled environment of the glovebox to get rid of contaminants directly before measurements take place.

After some initial training, tip and sample preparation in the glovebox are easy, and measurement conditions are much improved compared to measurements in ambient. The combination of the Flex-Axiom and a N2 glovebox allows very stable scan conditions of well-defined, clean surfaces. Thus, we have for example been able to perform some intensive research on H- and O-terminated diamond samples, which are strongly affected by H2O adsorption. Details can be found in the following articles:

Silicon-Vacancy Centers in Ultra-Thin Nanocrystalline Diamond Films

S. Stehlik, L. Ondic, M. Varga, J. Fait, A. Artemenko, T. Glatzel, A. Kromka & B. Rezek

Micromachines (2018) 9, 281

Water interaction with hydrogenated and oxidized detonation nanodiamonds — Microscopic and spectroscopic analyses

S. Stehlik, T. Glatzel, V. Pichot, R. Pawlak, E. Meyer, D. Spitzer & B. Rezek

Diamond and Related Materials (2016) 63, 97-102

Read more about glovebox implementations by Nanosurf.

Read more about research at the Nanolino Lab.